Fire situations are among the most unpredictable and perilous events that may occur to anyone. It’s not simply a beneficial idea to know how to safely escape out of a building during a fire; it’s a talent that could save your life. Fires in homes, workplaces, and factories damage or kill thousands of people every year. Even though there are guidelines to keep people safe, things often become worse when people panic or aren’t ready. You need to know more about fire safety than just putting in alarms and sprinklers. You need to be informed, plan ahead, and know how to accomplish things in order to move fast while you’re under stress. This article will go over safe ways to leave a building, tips from experts, and lessons acquired from real-life scenarios. Learning about how fire works and how to figure out how dangerous it is Fires don’t always spread in the same way. It depends on how flammable the materials are, how air circulates, and how the building is put up. For instance, a fire in a kitchen can spread quickly because grease burns easily, but a fire in an office may spread more slowly. Experts suggest that a fire risk assessment should look at how many people are there, how easy it is to get out, and where fires might originate. It is very vital to figure out how long it is safe to depart. If a normal corridor can fit 1.3 persons per meter of width every second, then a 2-meter-wide corridor with 50 people in it might potentially clear in roughly 19 seconds. But in real life, panic often makes such evacuations take longer, which shows how vital planning and drills are. Planning and Getting Ready for Evacuation Routes The first step to a successful evacuation is to make a plan. Find more than one way out and make sure they are constantly open. Fire doors should be easy to find and work. They should also have bright signage that helps people find their way even when there is smoke. Many safety experts, including fire protection specialist John Driscoll, warn that “having a backup exit can mean the difference between life and tragedy.” When you make preparations, think about populations who are more likely to get wounded, such as kids, seniors, and persons with disabilities. Give them people to help them go out of the building, and make sure the paths are broad enough for anyone who needs mobility aids. Fire Drills: The Real-Life Test Regular fire drills are important for getting people used to how to respond. According to a study by the National Fire Protection Association (NFPA), offices that ran drills every three months were 40% more likely to get people out of the building on time. Drills help people learn how to stay low to avoid breathing in smoke and how to locate exits when they are stressed. For example, during a simulated drill in a lofty structure, the people who took part were timed as they left. People who stuck to their allotted responsibilities and were calm went out in less than four minutes. It took approximately seven minutes for those who weren’t ready, which shows how crucial it is to be ready. What to Do When the Fire Alarm rings. You have to do something straight away when you hear a fire alarm. Don’t make any assumptions, like waiting to see if the fire is real. Every second is important. To keep from breathing in too much smoke, crouch low to the ground, cover your mouth and nose with a cloth, and move rapidly to the nearest safe exit. It’s also very crucial to keep away from lifts. Stairs are the safest way to get out of a building when there are fires because electrical systems can cease working or people can become stuck. Experts recommend to “crawl and walk” if the smoke is dense. You may see better and breathe cleaner air when you crawl. Talking when leaving It’s incredibly crucial to talk to each other amid situations, but people often fail to do so. Tell folks where to go by using already set signals or smartphone alerts. For large buildings, make sure that floor wardens sweep the floors and help people exit in an orderly way. Many people died in the 2017 Grenfell Tower fire in London because of uncertainty and sluggish communication. Analysts found that better communication, such as simple audio alerts and instructions that were customised for each floor, might have greatly reduced the number of deaths. How to Use Fire Safety Tools Fire extinguishers, sprinklers, smoke detectors, and emergency lights are all highly crucial for getting people out safely. Knowing how to use a fire extinguisher can save lives if the fire is small and easy to put out. Staff who know how to use fire extinguishers rapidly put out a tiny electrical fire in a hotel kitchen, stopping an emergency from spreading across the building. On the other hand, trying to put out a bigger fire without training caused injuries. This episode highlights the rule: use equipment correctly and leave if you’re not sure. Things to Keep in Mind for High-Rise Buildings It is very challenging to put out fires in high-rise buildings. There might be many people in the stairwells, which could make the evacuation take longer. Smoke can also rise through holes and cracks. Experts suggest that floors that aren’t under immediate danger should stay put, coupled with effective communication and smoke-proof safe locations. Numerical insight: If everything goes perfectly, it may take 10 to 15 minutes to get 200 people out of a 20-storey structure. Considering panic and physical limits can add 20 to 25 minutes to the time it takes to evacuate, which highlights how crucial it is to have several levels of evacuation strategies. What Worked and What Didn’t in Real Life In 1980, the MGM Grand Fire in Las Vegas killed 85 people. After the fire, all buildings

Industrial Electrical Work: Global Safety Standards, Risk Assessment & Best Practices

Industrial electrical work has evolved into a critical foundation for modern organizations. Factories, data centers, hospitals, logistics hubs, and corporate campuses depend on reliable electrical systems to operate without interruption. The economic impact of electrical failure can be enormous. A 30-minute outage in a mid-sized manufacturing plant can stop production worth USD 25,000, according to industry estimates. This reality makes industrial electrical work and electrical work in industry strategic functions rather than only technical tasks. As industries adopt automation, IoT sensors, robotics, and clean-energy systems, electrical infrastructures have become more complex. Organizations now require advanced electrical planning, high-precision installation, continuous monitoring, and rigorous electrical risk assessment. In this environment, electrical work defines not only operational stability but also long-term competitiveness and safety. Yet many companies underestimate the consequences of poor electrical maintenance. A study by two European insurers found that nearly 22 percent of industrial fires originate from electrical faults. Another survey conducted in Southeast Asia revealed that over 35 percent of factories operate with outdated wiring systems installed more than 20 years ago. The data is clear: without structured electrical management, workplace safety becomes fragile and business continuity collapses. What Is Electrical Work in Industry? A Modern Definition Industrial electrical work refers to the design, installation, operation, inspection, and maintenance of electrical systems in industrial and organizational settings. These systems include power distribution, motors, control panels, sensors, backup systems, circuit protection, and specialized machinery. In a modern context, industrial electrical work goes beyond wiring and circuits. It includes energy optimization, electrical safety planning, predictive maintenance, automation support, and electrical data analytics. Engineers now rely on thermal cameras, IoT-based monitoring, and advanced testing equipment to evaluate system health. Understanding what is electrical work in industry requires examining three core dimensions: The first is technical reliability, which ensures that power systems operate continuously under varying loads. The second is safety compliance, a legal requirement that reduces the risk of fire, shock, or equipment failure. The third is operational efficiency, allowing industries to minimize losses, reduce downtime, and extend equipment lifespan. Global standards such as IEC, NEC, BS 7671, and ISO 45001 influence these practices. Good electrical work blends engineering precision with regulatory discipline. Why Industrial Electrical Work Matters in a Globalized Economy Modern supply chains allow no tolerance for downtime. If a food-processing plant in Thailand experiences a two-hour outage, it may fail to ship products to a supermarket chain in Dubai. A semiconductor facility in Malaysia cannot afford voltage fluctuations even for a few milliseconds because it may damage wafers worth millions. Electrical stability has become an economic and strategic requirement. Organizations now confront three global challenges: The first is rising energy cost volatility. Even a 5 percent increase in industrial tariffs forces companies to optimize electrical systems. The second is the growing dependence on automation, which demands clean, stable power. The third is increasingly strict regulatory environments, especially in Europe, North America, and parts of Asia, requiring strict workplace electrical safety practices. Industries that manage electrical systems effectively avoid accidents, achieve sustainability goals, and protect employees. Those that fail often face reputational damage, production delays, and legal penalties. Electrical Risk Assessment: The Foundation of Workplace Electrical Safety Electrical risk assessment is the systematic evaluation of electrical systems to identify hazards, quantify risks, and implement mitigation strategies. Global experts often describe it as the “first line of defense against electrical uncertainty.” A typical risk assessment includes load analysis, insulation checks, wiring inspections, protective device testing, and thermal scanning. Modern assessments incorporate predictive maintenance tools that detect anomalies before they escalate. Consider a case from a logistics warehouse in Turkey. Routine thermal imaging detected a circuit breaker operating at 98 degrees Celsius. Although the equipment still functioned, the temperature exceeded safe limits. Engineers replaced the breaker for USD 140, preventing a potential failure that could have caused a USD 20,000 warehouse shutdown. This example illustrates the mathematical logic of risk assessment: small investments prevent large losses. An American safety consultant summarized it effectively: “Electrical risk assessment is not paperwork; it is financial protection disguised as engineering.” Global Standards Shaping Industrial Electrical Work International standards guide organizations in building safe and reliable electrical systems. These include: IEC standards, which influence most European and Asian markets. NEC, the benchmark for North America. ISO 45001, guiding workplace safety management. BS 7671, widely used in the UK and Commonwealth regions. Compliance is not optional. Many global companies require suppliers to maintain specific electrical certifications before awarding contracts. Failure to comply may result in fines or contract termination. A manufacturing plant in Eastern Europe learned this hard lesson. After repeated voltage irregularities caused machine downtime, an audit revealed unapproved modifications to the power distribution board. The plant received a compliance warning that threatened a USD 3 million export contract. After upgrading equipment, calibrating breakers, and implementing documentation standards, the plant avoided the penalty. Compliance became a business advantage. The Economics of Electrical Maintenance: Cost, Loss, and ROI Electrical maintenance is an investment, not an expense. When calculated properly, its return on investment is substantial. If a plant spends USD 15,000 annually on electrical inspections and preventive maintenance, and prevents outages worth USD 120,000, the ROI exceeds 700 percent. Even basic tasks—tightening loose connections, balancing loads, or replacing old capacitors—reduce energy waste by 2 to 5 percent. A textile mill in Bangladesh reduced energy losses by 3.7 percent after reorganizing its power factor correction system. The cost of the upgrade was USD 4,800. The company recovered the investment in six months. These examples show that maintenance contributes directly to profitability. Modern Technologies Transforming Industrial Electrical Work Industrial electrical work has moved beyond manual tools. Today’s systems use digital instruments that deliver high precision. Technologies include IoT sensors for load monitoring, AI-driven fault prediction, thermal imaging for heat analysis, smart breakers that track data, and energy management software. For example, an IoT-based monitoring system installed in a Malaysian electronics factory reduced downtime by 18 percent within one year. The sensors detected early signs of transformer vibration, allowing

Fire Safety Compliance Standards in Bangladesh: Complete Guide to Rules, Risks, and Smart Safety Practices

Fire safety has become a national priority for Bangladesh. With rapid industrial growth, dense urban structures, and increasing commercial activity, the country faces one of the highest fire-risk environments in South Asia. The frequency of fire incidents in factories, markets, and residential high-rises shows why Fire Safety Compliance Standards must be followed rigorously. As cities like Dhaka, Chattogram, Narayanganj, and Gazipur expand vertically, fire safety is no longer an optional practice; it forms the backbone of sustainable urban development. In Bangladesh, fire safety compliance rules derive mainly from the Bangladesh National Building Code (BNBC), the Fire Prevention and Fire Fighting Act, and guidelines issued by Bangladesh Fire Service & Civil Defence (FSCD). These define how buildings must be designed, equipped, and maintained to prevent fire incidents and reduce casualties. Unfortunately, many structures fail to meet even minimum compliance requirements, resulting in tragic incidents at FR Tower, Nimtoli, Chawkbazar, Bailey Road, and dozens of industrial zones. This article explores Bangladesh’s fire safety compliance landscape using globally recognized standards, local laws, real-case insights, calculations, expert opinions, and practical examples. Whether you operate a business, design buildings, or work in facility management, this guide will help you understand how to apply safety-first principles effectively. Understanding Fire Safety Compliance Standards in Bangladesh Fire Safety Compliance Standards in Bangladesh combine global codes with local regulations. The goal is to minimize risks by ensuring that all buildings—industrial, commercial, residential, or institutional—meet minimum fire protection requirements. The core components include: Structural fire protection Fire detection and alarm systems Firefighting equipment Evacuation routes Passive and active protection Regular maintenance and inspection User training and emergency preparedness According to FSCD data, Bangladesh reported over 25,000 fire incidents in 2023 alone, causing losses exceeding several hundred crores. Many investigations revealed that buildings lacked proper alarms, sprinklers, or emergency exits—problems directly related to non-compliance. Fire expert Engr. Ahmed Hasan notes: “In Bangladesh, 60–70% of fire losses occur not because systems are absent, but because they are non-functional, poorly installed, or never maintained.” This reality underscores why understanding compliance rules is a national responsibility, not just a regulatory formality. The Regulatory Framework: BNBC, Fire Service Rules, and Local Authority Requirements Bangladesh enforces fire safety primarily through three pillars: 1. Bangladesh National Building Code (BNBC 2020) BNBC sets detailed requirements for: Fire-resistant materials Compartmentation Exit routes Smoke management Fire lifts Fire hydrant and sprinkler systems Emergency power and lighting For example, BNBC requires: Minimum two staircases for buildings above 10 stories 2–4 hours fire-resistance rating for structural elements of high-rises Fire detection systems in all commercial buildings 2. Fire Service & Civil Defence (FSCD) Regulations FSCD issues: Fire safety approval certificates Annual renewal certificates Occupancy-level fire safety assessments Guidelines for hydrants, pumps, extinguishers, evacuation, and training FSCD also provides enforcement action, sealing non-compliant buildings when needed. 3. RAJUK / Local Authorities For Dhaka, RAJUK requires mandatory fire safety clearance before issuing completion or occupancy certificates. Despite these frameworks, enforcement remains a challenge because organizations often delay compliance investments, leading to high-risk environments. Designing Fire-Safe Buildings in Bangladesh: Structural and Architectural Compliance Ensuring safety starts at the design stage. BNBC and FSCD require architects and engineers to incorporate protection features that withstand the intense heat and rapid flame spread typical of urban Bangladeshi fires. Fire-Resistant Structure Concrete buildings can withstand fire longer than steel structures. Steel loses 50% of strength at around 550°C, and in Bangladesh’s congested zones, fire can reach this temperature within 8–10 minutes. Fireproofing coating can extend structural survival time by 120–180 minutes—critical for evacuation and rescue. Compartmentation to Slow Fire Spread BNBC requires: 1–2 hour fire-rated walls 60–120 minute fire doors Fire stops in vertical shafts Case Example: During a warehouse fire in Tongi, a single fire door successfully delayed smoke spread for 45 minutes, allowing full evacuation. The FSCD report stated that “the damage would have been four times greater without proper passive protection.” Safe Escape Routes Key requirements include: Minimum 1.1–1.5 meter corridor width Two exits for large halls and factories Fire-rated stairwells with pressurization Emergency lights for at least 90 minutes Many tragedies in Bangladesh occurred due to locked exits or narrow staircases—problems compliance rules aim to eliminate. Fire Detection and Alarm Systems: Bangladesh Compliance Rules That Save Lives Early detection is crucial. BNBC and FSCD require smoke detectors, heat detectors, alarm sounders, and manual call points across public and private facilities. Why Detection Speed Matters In Bangladeshi environments—especially garment factories, kitchen-heavy restaurants, and markets—fire grows extremely fast due to high fuel loads. Smoke detectors can detect fires within 10–30 seconds, while heat detectors may take minutes longer. This delay can allow flames to double several times. Real Case: Bailey Road Restaurant Fire (2024) Investigation reports highlighted that: Exhaust systems were unclean Early detection was insufficient Fire spread through ducts Panic occurred due to lack of alarms This incident proved that even commercial spaces where customers gather must follow strict detection standards. Bangladesh Expert Insight Fire consultant Brig. Gen. Md. Main Uddin (FSCD Director General) often emphasizes: “A fire detector costs less than a family dinner, yet its absence can destroy an entire community.” Active Fire Protection Systems: Hydrants, Sprinklers, Pumps, and Gas Suppression Active systems directly fight or control fire. FSCD requires all multi-story buildings, factories, shopping malls, and warehouses to install: Automatic sprinklers Fire hydrants Standpipe and hose systems Fire pumps (electric + diesel backup) FM200 or CO₂ suppression for server rooms The Math Behind Sprinkler Efficiency A single sprinkler head discharges 60–70 liters of water per minute. If a fire requires 250 liters/min to contain early flames, activating four heads can stabilize most room fires within minutes. Failure Case in Bangladesh Industry In a garment factory in Gazipur, sprinklers were installed but the diesel backup pump was non-functioning. A power cut disabled the system during a fire, resulting in losses exceeding Tk 40 crore. The audit noted: “System existed but compliance did not.” This example shows why Bangladesh’s industrial compliance must include both installation and functional readiness. Fire Doors, Smoke Control, and Passive

Fire Safety Checklist for Businesses: A Global Guide to Preventing Disaster

Introduction In today’s fast-paced world, fire safety is important for all businesses, big and small. Following the rules is only part of having a good fire safety checklist for businesses. It’s also about keeping people, property, and reputations safe. A fire can be very bad. People can die, businesses can have to close, reputations can be ruined, and money can be lost. But a lot of companies don’t pay attention to basic, regular fire risk management. According to one insurance company’s data, “there is a structure fire every 63 seconds” in the US. (Frankenmuth Insurance) This means that a regular business could have a fire without any warning. Fire safety is a strict plan that everyone, no matter where they live, how big their business is, or what industry they are in, should know about and follow. This article gives businesses a professional, useful guide to the fire safety checklist that works all over the world. We’ll look at how to build, check, and keep up practical fire safety systems using real-life examples, small calculations, expert opinions, and stories of both success and failure. In the end, you’ll have useful tips that you can use in your own business. Why a Fire Safety Checklist Is Important for Businesses First, let’s make it clear that a fire safety checklist is more than just checking off boxes. For a lot of businesses, this list is what keeps things running smoothly and stops disasters from happening. Knowing What Risk and Impact Mean Not all fires are about flames. Smoke, poisonous gases, and the building falling down can be more dangerous to life than the flames alone. For instance, fire safety expert David Anthony Purser has shown that smoke and toxic combustion products are very important in situations where people have to leave quickly to save their lives. If operations are stopped for weeks, the cost of a fire in a warehouse that stores flammable materials could be ten times the cost of repairs. Following the Rules and Doing Your Homework Laws in many countries say that businesses must check for fire hazards, put in safety systems, and keep records. For example, the UK’s Regulatory Reform (Fire Safety) Order 2005 says that the “responsible person” is in charge of doing fire risk assessments. Following the rules keeps people and your brand safe and avoids fines. Insurance and Keeping Your Business Running From the point of view of the insurance company, a strong fire safety program lowers the chances of a fire happening and the amount of damage that happens when it does. A fire safety checklist for businesses is a way to control risk and show insurers and other stakeholders that you are taking steps to protect your business. Implementation That Works vs. Implementation That Doesn’t Work • A mid-sized factory was able to improve when it started doing monthly checks of its firefighting equipment, quarterly drills for evacuating, and keeping track of open deficiencies. When a small electrical problem started a fire in an empty area, the automatic suppression system worked. People were quickly moved out, and the downtime was only half a day. • Failure story: A chain of stores didn’t pay attention to fire doors that were blocked and fire extinguishers that were out of date. A small fire in the kitchen spread through ductwork that wasn’t visible. It took 17 minutes to get everyone out instead of the planned 3 to 5 minutes because the smoke alarms didn’t work. The result: a lot of damage to the brand and big problems for the business. Step-by-Step Review Before using any equipment or drills, every business needs to do a structured risk assessment. This is the first thing you need to do to make a fire safety checklist for businesses. Look for things that could start a fire, like things that can catch fire, electrical hazards, kitchens, and heating systems. Find people who are at risk, such as staff, visitors, contractors, and people with disabilities. Use controls like keeping things clean, storing things safely, and getting rid of things that could start a fire to check and lower the risk. Write down what you find and the things you do that are most important. Go over and change it at least once a year or when big changes happen, like when the layout or occupancy changes. (For OHEAP, Fire, and Security) Using It in the Real World and Doing Small Calculations Let’s say your warehouse is 500 square meters and has drums that hold 300 liters of solvent. The fire-load calculation: the solvent weighs about 0.8 kg/L, so 300 L weighs about 240 kg. The heat of combustion is about 43 MJ/kg, so the total heat is about 10,320 MJ. You now have a high-fire-load zone that needs better suppression and good compartmentation as part of your risk assessment. Expert Advice A UK consulting firm that specializes in business fire risk services says, “Fire safety must be a continuous thread throughout your business—not just a once-a-year tick-box exercise.” (Specialists in Fire Safety) Helpful Advice • Choose a person to be in charge of fire safety.• Write down hazards and controls on a template checklist (there are many free ones available online).• Re-evaluate every time the layout, process, or equipment changes a lot.• When they check documents, auditors often look for the “latest version.” Cleaning the House and Making Sure It Doesn’t Catch Fire After looking at the risks, the next step on a business’s fire safety checklist is to focus on preventing fires and keeping the place clean. This means keeping an eye on fuel loads and lowering the chances of a fire starting. How to Control Sources of Fire and How to Stop Them Bad wiring, overloaded outlets, hot surfaces, and smoking materials are all common causes of fires. The insurance industry asks businesses on its checklist, “Are extension cords always in use?” Are the sprinklers blocked? Frankenmuth Insurance says it’s a good idea to check electrical panels once a

Best Fire Extinguisher for Home Use in Bangladesh – Fire Safety Made Simple

Introduction: Why Every Home Needs the Right Fire Extinguisher In Bangladesh, where densely packed housing and unreliable electrical systems are common, fire safety is not just a concern—it’s a necessity. According to data from the Fire Service and Civil Defence (FSCD), over 25,000 fire incidents were reported nationwide in 2024, resulting in significant property loss and tragic fatalities. Yet, most households still lack a basic fire extinguisher, the simplest line of defense between a small spark and a devastating fire. Choosing the best fire extinguisher for home use is often overlooked until disaster strikes. Many homeowners assume that all extinguishers are the same or that they’re only needed in factories or commercial spaces. The truth is, the difference between a small kitchen mishap and a house burned to the ground often lies in owning the right extinguisher—and knowing how to use it. Let’s explore what makes a fire extinguisher truly effective, which types suit your home best, and how to ensure your investment translates into real protection. Understanding Fire Types: The Science Behind Choosing Right Not all fires burn alike. Different materials ignite and burn in unique ways, requiring different extinguishing agents. Fire experts categorize fires into five main classes: Class A: Ordinary combustibles—paper, wood, fabric, plastics. Class B: Flammable liquids—petrol, diesel, oils, grease. Class C: Electrical fires—short circuits, wiring, appliances. Class D D: Combustible metals—rare in homes. Class K (or F): Cooking oils and fats—common in kitchen fires. Most residential fires in Bangladesh fall under Class A, B, or C, and sometimes K (especially in kitchens). Therefore, a multi-purpose ABC or BC fire extinguisher is ideal for household use. What Makes the Best Fire Extinguisher for Home Use The best fire extinguisher combines versatility, ease of use, and quick deployment. A high-quality ABC dry chemical extinguisher, for instance, can handle most home fire scenarios efficiently. 🔹 1. ABC Dry Chemical Extinguishers Agent: Monoammonium phosphate. Effective for: Class A, B, and C fires. Advantages: Versatile and affordable. Example: A 2 kg ABC extinguisher can discharge for around 12 seconds, enough to suppress a small kitchen or electrical fire. Best for: Homes, offices, and apartments. 🔹 2. CO₂ (Carbon Dioxide) Extinguishers Effective for: Class B and C fires. Advantages: Leaves no residue; safe for electronics. Best for: Homes with computer setups, electric panels, or studios. Note: Not effective on wood or fabric fires. 🔹 3. Wet Chemical Extinguishers Effective for: Class K fires (cooking oils, fats). Ideal for: Modern kitchens, restaurants, and homes using deep fryers. Example: A 3 L wet chemical extinguisher can suppress a 600 ml oil fire within seconds without reignition. 🔹 4. Water and Foam Extinguishers Effective for: Class A fires only. Caution: Never use on electrical or oil fires. How to Choose the Right Size and Model Home extinguishers come in various sizes—usually 1 kg to 5 kg for domestic use. Larger extinguishers last longer but are heavier. A good practice is to keep: 1 kg ABC extinguisher in the kitchen or near electrical boards. 2 kg or 4 kg ABC or CO₂ extinguisher near the main exit or in the living area. Calculation Example: A 2 kg ABC extinguisher covers approximately 30–40 sq ft of fire area if discharged promptly. For an average 1000 sq ft home, at least two extinguishers in separate zones are recommended for quick accessibility. Real-Life Illustration: When a Small Extinguisher Saved a Family In 2023, a Dhaka apartment experienced a short circuit in the refrigerator late at night. The family, awakened by the smell of smoke, managed to suppress the fire with a 2 kg CO₂ extinguisher they had purchased only months earlier. The fire service later confirmed that without it, the blaze could have spread to adjacent flats within minutes. This real incident illustrates why fire safety begins at home, not at the fire station. Common Mistakes Homeowners Make Buying the wrong type: Many households mistakenly buy water-based extinguishers, which are ineffective for electrical fires. Ignoring expiry dates: Most extinguishers last 3–5 years. Regular servicing ensures reliability. Placing it out of reach: Extinguishers stored behind cupboards or under sinks are useless in emergencies. Lack of training: In panic, even the best extinguisher fails if no one knows the PASS method—Pull, Aim, Squeeze, Sweep. Expert Insights: What Fire Professionals Recommend “Every home should have at least one multi-purpose extinguisher within five meters of the kitchen.” says Engr. Md. Mahmud Hasan, a fire safety consultant and former FSCD officer in Dhaka. “But equipment alone doesn’t save lives—awareness and maintenance do.” Hasan’s advice mirrors international fire safety standards. The NFPA (National Fire Protection Association) in the U.S. also recommends regular inspection, monthly visual checks, and annual professional servicing. In Bangladesh, local suppliers such as Safety Source Ltd. and FlameStop BD provide certified UL-listed extinguishers and refilling services, ensuring compliance with safety norms. Maintenance and Refill: The Often-Ignored Essentials A fire extinguisher is only as good as its condition. Dust, corrosion, or pressure loss can render it useless. Homeowners should: Check the pressure gauge monthly. The needle should stay in the green zone. Invert the extinguisher gently every few months to prevent the powder from settling. Schedule a professional servicing every 12 months. Replace or refill after every use, even partial. A refill in Bangladesh typically costs between ৳300 and ৳600 for small models, a fraction compared to property or life loss. Safety First: Building a Fire-Safe Home Culture Owning the best fire extinguisher is one thing; fostering a safety-first mindset is another. Families should educate all members—especially children—about basic fire response: Keep emergency numbers visible near phones. Know at least two exit routes. Never re-enter a burning building. Fire drills might sound excessive for a home, but even a 10-minute family practice once a year can make the difference between chaos and control. Failure Story: When Preparation Wasn’t Enough In contrast, a tragic incident in Chattogram in 2022 involved a gas stove explosion. The family owned an extinguisher—but it had expired five years earlier. When they tried to use it,

Fire Door Bangladesh: UL Listed Fire Doors, Standards, and Safe Installation

Standards, Certifications, and How UL Listed Fire Doors Are Raising Safety Standards Across Industries Introduction In Bangladesh’s rapidly growing industrial and construction sectors, safety has moved from being an afterthought to a defining benchmark of credibility. Whether it’s a high-rise office, a factory in Savar, or an apartment in Uttara, one element silently safeguards hundreds of lives every day — the fire door. Fire doors are not just architectural accessories; they are engineered life-saving barriers designed to resist the spread of fire, smoke, and toxic gases. Yet, despite their crucial role, misconceptions remain widespread. Many facilities still confuse decorative steel doors with certified fire-rated ones, often discovering the difference only after a tragedy. This article dives into Fire Door Bangladesh — how international standards, certifications like UL Listed Fire Door Bangladesh, and professional installation practices are shaping a safer tomorrow. What Exactly Is a Fire Door and Why It Matters A fire door is a specially designed, tested, and certified door assembly that can contain fire and smoke for a specified period — typically 30, 60, 90, or 120 minutes. Unlike conventional doors, it integrates fire-resistant materials such as steel, gypsum, and intumescent seals. In real-life scenarios, a properly installed fire door can make the difference between a controlled incident and a catastrophe. For instance, during a 2023 garment factory fire in Gazipur, a correctly rated fire exit door Bangladesh installation allowed over 200 workers to evacuate safely within minutes — preventing potential fatalities. When installed correctly, a fire door acts as a passive fire protection (PFP) system, maintaining compartmentalization and buying valuable time for evacuation and emergency response. Fire Door Standards: What Bangladesh Learns from Global Benchmarks Fire door standards vary worldwide, but the core principles remain consistent — structural integrity, insulation, and smoke control. The most respected certifications include: UL (Underwriters Laboratories) Standard UL 10C — The gold standard in the U.S. for fire-rated door assemblies. BS EN 1634-1 — The British and European test for fire resistance. NFPA 80 — Governs installation and maintenance of fire doors and other protective openings. In Bangladesh, forward-thinking companies increasingly demand compliance with UL Listed Fire Door Bangladesh standards, ensuring their buildings meet both local and global expectations. Regulatory agencies and international buyers now often require UL or BS EN certification as part of compliance audits — especially in the RMG (Ready-Made Garments) and export-oriented sectors. UL Listed Fire Door Bangladesh: What Makes It Different A UL Listed Fire Door isn’t just a marketing term; it’s an assurance of rigorous testing and verified performance. UL conducts standardized fire exposure tests that simulate extreme real-world conditions. For example, a 90-minute UL fire door must withstand temperatures above 1000°C without structural failure, allowing emergency crews enough time to respond. The door is also tested for smoke leakage and integrity after cooling, ensuring long-term durability. In Bangladesh, suppliers like Safety Source Limited import and install UL Listed Fire Doors from leading global manufacturers such as NAFFCO and ASICO, ensuring that every door meets international fire-safety benchmarks while complying with local installation standards. Fire Door Installation Dhaka: Why Expertise Matters More Than Material Even the best-certified fire door loses effectiveness if installed incorrectly. A minor gap of just 3 mm around the frame can render the door useless during a fire. Professional fire door installation in Dhaka requires specialized knowledge of frame alignment, sealing, and smoke-control accessories. For instance, an intumescent strip expands 5–10 times its volume when exposed to heat, sealing gaps around the door. But if the installer forgets to include it — or uses a cheap adhesive — smoke infiltration can occur within seconds. Industry experts recommend annual fire door inspections to ensure operational readiness. These include hinge checks, closer functionality, and seal condition reviews. As Engr. N. Rahman, a fire safety consultant at Dhaka’s Uttara Fire Division, notes: “Fire doors aren’t meant to look good — they’re meant to perform under stress. Installation and maintenance determine whether that door becomes a lifesaver or a liability.” Understanding Fire Door Accessories Bangladesh: The Hidden Heroes A fire door’s effectiveness depends as much on its accessories as on its core panel. Certified fire door accessories Bangladesh include: Fire-rated hinges tested for high-temperature endurance. Self-closing devices (door closers) ensuring the door automatically shuts during fire alarms. Panic bars allowing quick exit without keys. Smoke seals and gaskets preventing toxic gas spread. For example, a commercial tower in Banani replaced its standard door closers with certified UL listed hardware, which cost only 20% more but reduced annual fire risk assessment penalties by nearly 40%. Such measurable returns prove that compliance isn’t just about safety — it’s smart business. Economic and Regulatory Context in Bangladesh As industrial zones expand, fire-safety enforcement has tightened. The Bangladesh Fire Service and Civil Defence (FSCD) now mandates fire-rated doors in all high-occupancy and manufacturing facilities. Insurers and buyers also evaluate fire-door certifications during audits. Factories using UL Listed Fire Doors often qualify for lower insurance premiums and faster international approvals. In contrast, companies failing fire-door compliance have faced operational shutdowns and export rejections. In Dhaka’s industrial context, UL Listed Fire Door Supplier Dhaka certifications act as a silent business enabler — protecting lives, assets, and brand reputation simultaneously. Case Study: Two Buildings, Two Outcomes In 2022, two commercial facilities in Tongi faced electrical fires within a month of each other. The first, equipped with UL certified fire doors installed by a professional vendor, contained the fire to a single floor for nearly two hours. Damage was limited to 15%, and no casualties were reported. The second building used untested local steel doors. Within 20 minutes, flames spread through stairwells, causing extensive structural loss and halting business for three months. The contrast highlights a simple truth: the cost of non-compliance far exceeds the price of a certified fire door. Global Best Practices: Lessons Bangladesh Can Adopt Countries like Singapore and the UAE have integrated fire-door compliance into every phase of construction — from blueprint approval to periodic inspection. Bangladesh’s urban developers

Fire Detection System in Bangladesh: A Complete Guide to Modern Fire Safety

Introduction: Why Fire Detection Systems Are Vital for Bangladesh In recent years, Bangladesh has witnessed rapid industrialization—sprawling factories, high-rise offices, and dense urban growth. But this growth has come with a dangerous cost: an alarming rise in fire incidents. From the Tazreen Fashions fire (2012) to the Banani FR Tower blaze (2019) and Chawkbazar explosion (2019), every tragedy revealed one painful truth—the lack of an early fire detection system turns minor sparks into national disasters. According to the Bangladesh Fire Service and Civil Defence (FSCD), over 24,000 fire incidents were reported in 2023 alone, causing property damage worth Tk 500 crore and hundreds of fatalities. Many of these could have been prevented or minimized through effective fire detection systems. Fire detection isn’t just a compliance requirement—it’s the first and most essential step toward building a safer Bangladesh. What Is a Fire Detection System and How Does It Work? A fire detection system automatically identifies signs of fire—smoke, heat, or flame—and sends an immediate alert. This gives occupants and responders crucial time to act before the situation spirals out of control. Every system has three core components: Detectors or Sensors – These detect smoke, heat, or flame. Control Panel – The system’s “brain” that receives signals and activates alarms. Notification Devices – Sirens, strobe lights, or messages that warn occupants and alert fire services. In Bangladesh, many modern commercial buildings now integrate these systems with fire alarms, sprinklers, and even IoT-based monitoring platforms, providing real-time status updates to facility managers. Fire Detection in Bangladesh’s Industrial and Commercial Sectors Factories, especially ready-made garment (RMG) and textile plants, form the backbone of Bangladesh’s economy. Yet, they are also the most vulnerable to fire hazards due to high-density materials, electrical machinery, and human activity. Take for example, the Narayanganj factory fire in 2021, which killed over 50 workers—many trapped inside due to blocked exits and no early warning. The investigation found that the fire detection and alarm systems were either absent or non-functional. After that tragedy, many compliant factories in EPZs (Export Processing Zones) and BGMEA-certified zones upgraded their facilities with advanced detection systems—photoelectric smoke detectors, addressable control panels, and heat sensors for dyeing units. As a result, several near-incidents since then were detected early and controlled swiftly. This shift underscores a major lesson: fire detection is not optional—it’s operational survival. Different Types of Fire Detection Systems Used in Bangladesh Fire detection technologies used in Bangladesh can be categorized as: 1. Smoke Detectors Common in offices, malls, and hospitals. They detect airborne smoke particles using ionization or photoelectric sensors. 2. Heat Detectors Used in kitchens, manufacturing areas, and power plants. They activate when temperature exceeds a set threshold (e.g., 57°C). 3. Flame Detectors Essential for fuel storage areas and chemical industries. These sense UV or IR radiation from flames. 4. Aspirating Smoke Detectors (ASD) High-end systems that continuously sample air—ideal for sensitive areas like data centers or server rooms in Dhaka’s tech parks. Most large facilities now prefer addressable fire alarm systems where each detector has a unique code, allowing maintenance teams to locate and fix faults within minutes. Cost and ROI: The Economics of Fire Detection in Bangladesh For many Bangladeshi business owners, the first question is: “How much will it cost?” Let’s break it down with an example. For a 10,000 sq. ft. factory: Installation cost: Tk 300–600 per sq. ft. (depending on system type) Annual maintenance: Tk 50,000–1,00,000 Average fire damage (if undetected): Tk 2–3 crore Even a single prevented incident can yield a return on investment (ROI) exceeding 1,000%. Beyond money, consider the human cost—each life saved, each worker’s safety preserved, and the brand reputation maintained before global buyers like H&M, Zara, or Uniqlo. Technology and Innovation: Smart Fire Detection in Dhaka and Beyond Bangladesh’s growing smart building sector is embracing IoT-based fire detection systems. Companies in Dhaka and Chattogram are installing sensors that connect to cloud platforms, allowing real-time monitoring through smartphones. For example: SmartFire BD integrates AI with smoke detectors to distinguish between cooking smoke and actual fire. FireTech Solutions Dhaka provides addressable fire alarm panels linked to Building Management Systems (BMS). These systems can pinpoint the exact floor, room, or zone where smoke originates—reducing false alarms and response time from minutes to seconds. Integration with Broader Fire Safety Systems A modern fire detection system is just one part of a complete fire safety ecosystem. In an ideal setup: Smoke detectors trigger alarms. Fire doors automatically close. HVAC systems stop circulating air to prevent smoke spread. Sprinklers or gas-based suppression activate in targeted areas. Emergency exits light up, and evacuation announcements play through PA systems. Many large Dhaka buildings—like Bashundhara City, Square Headquarters, and Gulshan’s corporate towers—now follow this integrated model, significantly enhancing occupant safety. Case Study: A Success Story from a Dhaka RMG Factory A leading garment manufacturer in Gazipur installed an advanced fire detection system in 2022 as part of its LEED certification program. In early 2024, an electrical short in a finishing unit caused sparks at 3:15 AM. Within 45 seconds, the system detected the rise in smoke density and activated alarms. The control room notified FSCD, and sprinklers localized the fire before it spread. The damage was limited to less than Tk 5 lakh—compared to an estimated Tk 3 crore loss without early detection. The factory manager later said: “The system paid for itself in one night. Without it, we could have lost not just property—but people.” Common Failures and Pitfalls in Bangladesh Despite progress, fire detection failures remain common due to: Lack of maintenance: Dust and humidity damage sensors. Power interruptions: Backup batteries often missing. Improper installation: Detectors placed near vents or under fans. False alarms ignored: Frequent false triggers lead to complacency. The Fire Service and Civil Defence recommends quarterly system inspections and annual certification renewals, yet compliance remains low outside export-oriented sectors. Fire expert Engr. S. M. Rahman explains, “A fire detection system is not just a product—it’s a process. Without testing, calibration, and human awareness, even the most advanced

Boiler, Cylinder, and Compressor Inspection in Bangladesh | Industrial Safety & Compliance

Introduction Every thriving industrial sector stands on one non-negotiable pillar — safety. In Bangladesh, where manufacturing, textiles, shipbuilding, and energy industries are expanding rapidly, ensuring the safe operation of mechanical equipment such as boilers, cylinders, and compressors has become both a legal requirement and a moral obligation. The inspection and testing of these systems are not merely technical exercises; they are critical safeguards that prevent loss of life, protect assets, and ensure compliance with national and international safety standards. Authorized companies, certified by the Department of Inspection for Factories and Establishments (DIFE), carry out this responsibility with precision and accountability. Why Equipment Inspection Matters Industrial accidents are often traced back to neglected maintenance and uninspected machinery. Boilers can explode from unchecked pressure buildup, compressors may fail due to overloading, and cylinders can leak hazardous gases when corroded or damaged. A 2023 study by Bangladesh’s industrial safety authorities revealed that over 35% of industrial accidents involved uninspected or overdue equipment. Regular inspection mitigates these risks by ensuring mechanical integrity, operational efficiency, and worker safety. A Practical Illustration Imagine a textile factory operating a steam boiler rated for 10 bar pressure. Over time, sediment accumulation reduces its water level sensor accuracy. Without inspection, the pressure might exceed its safe limit, leading to a catastrophic explosion. However, a standard DIFE-approved inspection detects such anomalies early, preventing disaster and costly downtime. Legal Framework and Regulatory Oversight In Bangladesh, the Boiler Act 1923 and the Factories Act 1965, along with DIFE’s safety regulations, require periodic inspection of industrial boilers, compressors, pressure vessels, and gas cylinders. Each inspection is conducted by a licensed inspection engineer or an authorized inspection company under DIFE’s supervision. These inspections certify that the equipment meets the prescribed standards for pressure, temperature, safety valves, and operational reliability. Failure to comply can result in penalties, shutdown orders, or loss of factory licenses. More importantly, it exposes employees and property to significant safety risks — an unacceptable outcome in any modern industrial operation. Types of Equipment Covered Industrial inspection services in Bangladesh generally cover: Boilers: Steam, water-tube, and fire-tube boilers used in textile, chemical, and energy plants. Compressors: Air and gas compressors in manufacturing units, oil refineries, and construction sites. Cylinders: Gas cylinders, storage vessels, and pressure containers used in various industrial applications. Pressure Vessels: Storage tanks or reactors that contain liquids or gases under pressure. Lifting Equipment: Cranes, hoists, and elevators, which are often part of integrated inspection packages. Each type of equipment demands specialized testing techniques, including ultrasonic thickness measurement, hydrostatic pressure tests, leak detection, and valve calibration. The Science Behind Inspection and Testing Inspection is both an art and a science. It involves a series of engineering evaluations that identify fatigue, corrosion, and deformation before failure occurs. For instance, during a boiler inspection, engineers may calculate the Maximum Allowable Working Pressure (MAWP) using formulas that consider shell thickness, material strength, and temperature coefficient. A simplified version of the formula looks like this: MAWP = (2 × t × S × E) / (R × F) where t = wall thickness, S = tensile strength, E = weld efficiency, R = radius, and F = safety factor. This kind of technical assessment ensures the equipment’s safe operational range and helps factories plan predictive maintenance schedules rather than waiting for breakdowns. Why DIFE Authorization Matters The Department of Inspection for Factories and Establishments (DIFE) is the governing authority in Bangladesh that ensures industrial safety compliance. Only DIFE-approved inspection companies are permitted to conduct official testing and certification. These organizations employ qualified mechanical and safety engineers, use calibrated instruments, and follow recognized testing standards such as ASME, API, or BSI. Authorization by DIFE guarantees that inspection reports are legally valid and accepted by both national regulators and international buyers — a critical factor for export-oriented industries such as garments, pharmaceuticals, and shipbuilding. Benefits of Regular Industrial Equipment Inspection 1. Enhanced Safety and Reliability Periodic inspection reduces the likelihood of catastrophic failures. A well-maintained compressor consumes less energy, operates smoothly, and minimizes downtime. 2. Cost Efficiency Early detection of cracks or corrosion prevents costly replacements. Preventive maintenance costs roughly 30–40% less than emergency repair or total replacement. 3. Legal and Insurance Compliance Factories that maintain up-to-date inspection records find it easier to renew licenses and obtain industrial insurance. 4. Environmental Protection Leaking cylinders or defective boilers can emit harmful gases or pollutants. Regular inspection helps align operations with environmental sustainability goals. A Tale of Two Factories: A Success and a Failure In 2022, a food processing plant in Gazipur suffered severe financial loss after a compressor explosion halted production for three weeks. The post-incident investigation revealed that the compressor had not been tested for two years. In contrast, a competing facility nearby conducted semi-annual industrial equipment safety inspections and faced zero downtime that year. Their preventive maintenance program saved an estimated BDT 4.5 million in lost production costs — a clear example of how inspection translates directly to profitability. Expert Insight “Inspection is not an expense; it’s an investment in operational security,” says Engr. Rahman Kabir, a certified mechanical engineer and industrial safety consultant in Dhaka. “Factories that budget for periodic testing avoid unpredictable failures and ensure continuous production flow.” Globally, industries that adopt a culture of preventive inspection see a 25–50% increase in equipment life expectancy, according to international industrial safety reports. Global Relevance: Lessons from Abroad Countries like Japan, Germany, and Singapore have integrated inspection systems linked to their national digital safety networks. Bangladesh is moving in the same direction, with DIFE gradually implementing digital tracking for inspection certificates and renewal alerts. Such modernization ensures transparency, improves safety data management, and aligns Bangladesh’s industrial safety practices with ISO 45001 and ASME Boiler and Pressure Vessel Code standards. Choosing an Authorized Inspection Company When selecting an authorized inspection company in Bangladesh, consider: DIFE authorization certificate number and validity. Experience with relevant industrial sectors. Use of advanced non-destructive testing (NDT) equipment. Qualified and licensed inspection engineers. Transparent reporting and after-inspection support. A reliable inspection

Fire Hydrant System Installation Dhaka — Ensuring Fire Safety & Industrial Protection

Introduction In the rapidly growing cityscape of Dhaka, the need for robust fire protection infrastructure has never been greater. When we focus on Fire Hydrant System Installation Dhdefense.In Dhaka, installation of fire protection systems is not simply about meeting regulatory requirements; it is about safeguarding lives, protecting assets, and ensuring the continuity of business operations under the principle of safety first. For industries and large-scale commercial developments, a dedicated hydrant network forms the backbone of fire safety and helps ensure that when a fire starts, it can be brought under control before it spirals. Globally, this principle is well understood: studies show that timely access to high-pressure water via hydrants or allied systems reduces fire spread, structural damage, and business downtime. (CORE POWER) In Bangladesh, the concept of fire protection for industry becomes especially critical due to the close proximity of industrial parks, dense residential blocks, and mixed-use high-rises. This article guides you through the entire process of installing a fire hydrant system in Dhaka, highlights real-life success and failure cases, explores cost considerations, and provides actionable guidance for planners, facility managers, and safety officers. Why a Fire Hydrant System Matters in Dhaka A well-designed hydrant system is a strategic investment in fire safety and operational resilience. In the urban context of Dhaka: High-density zones, mixed-use buildings, and industrial clusters elevate the risk of fire spread due to their proximity and complexity. A fire hydrant system ensures a reliable, high-pressure water supply is ready for firefighting, which is crucial when every minute counts. (CORE POWER) From a business continuity perspective, fires can shut down operations, destroy crucial inventory, and damage brand reputation. One Mumbai commercial complex reported that installing a hydrant system helped them negotiate lower insurance premiums and smoother regulatory approvals. (ecofireworks.in) In Bangladesh, many industrial facilities operate near densely populated areas, making fire protection not only a concern for the factory itself but also for the surrounding community, infrastructure, and environment. An illustrative scenario: Suppose a mid-sized manufacturing unit in Dhaka has 1,500 m² of floor area and inventory valued at US$1.2 million. A fire breaks out. Without a hydrant system, firefighting must rely on portable pumps or bucket-lines,m² ofbucket lines, possibly taking 10–15 minutes to establish effective flow. With a hydrant system designed for say 1bucket lines,, say,,200 l/min at 7 bar pressure (a feasible target), the fire department can start attack imm, say,the attackediately, reducing damage by perhaps 30-50 the attack%% and shortening downtime by days. That alone could justify the cost of installation many times over. An expert in the fire-protection field says: “A single error in planning or installation can render the system ineffective when lives depend on it most.” (ecofireworks.in) This underscores that it’s not only the presence of the system, but its% but also correct design, installation but alsoinstallation,and maintenance that makes it work. Key Components and Design Principles of a Hydrant System System Architecture At its core, a fire hydrant system consists of underground and above-ground pipes, landing valves or hydrant outlets, a water supply (often from dedicated tanks and pumps), control valves, and various accessories. (Efficient Fire) The design must ensure coverage of the entire risk area, adequate flow and pressure, and accessibility for firefighters. Design variables and practical calculation When designing a facility in Dhaka (or similar), you’ll consider the following factors: area covered (m²), occupancy and fire load, building height, available water supply, pipe sizing, and hydrant spacing. For instance, you might aim for a flow rate of 1,000 l/min at 6–8 bar for a 2,000 m² warehouse. If the municipal supply only provides 300 l/min at that pressure, you’ll need a fire pump and dedicated tank. Mini calculation: Suppose you need 1,000 l/min. The flow equation (approximate) is (Q = C A \sqrt{2gH}), but simplifying for hydrants, you look at pipe diameter. If you choose a 150 mm diameter pipe (with an internal area of approximately 0.0177 m²) and aim for a velocity of 3 m/s, the flow can be calculated as flow = area × velocity = 0.0177 × 3 = ~0.053 m³/s, which equals 53 l/s or approximately 3,180 l/min. There is ample capacity available. But you must verify friction losses, length of run, number of bends, valves, etc. This is why a detailed hydraulics analysis is needed. Guidelines emphasisea flow ofemphasize these calculations. (variex.in) Location and spacing Hydrants must be placed such that no point in the protected area is too far from a hydrant connection and firefighters’ equipment. Accessibility, exposure to damage (vehicles), and proper clearance are all important. For example, in the U.S. standard document: hydrantsemphasizedocument, hydrants “shall also be installed in a location where there is accessibility and in a safe location where there is a minimum possibility of damage from vehicles or injury to pedestrians.” (Scribd) Materials & construction Selecting durable materials (ductile iron, corrosion-resistant valves, quality fittings) is crucial. Without this, the system may degrade prematurely. A blog notes that hydrant systems are built to last with robust materials and require minimal maintenance if well installed. (Efficient Fire) Expert insight: “Selecting the right type of hydrants—pillar hydrants, post hydrants, or flush hydrants—matters depending on soil conditions and usage.” (variex.in) Fire Hydrant System Installation Dh—mattersInstallation inaka – Step-by-StInstallation in—Step-by-Stepep Guide Site assessment & regulation compliance Begin by surveying the property to identify the building layout, risk zones, available water sources, and accessibility for fire service vehicles. Then check with local authorities for required permits and fire-safety codes. In the Dhaka context, liaising with the local fire service and municipality is essential. Globally, this step is acknowledged as critical. (variex.in) Design and system layout Engage a qualified fire-protection engineer to design the pipe routes, water storage, pump sizing, hydrant spacing, hose source and spacing, and reel or landing valve placements. Use real risk data, spacing for occupancy types, and fire load metrics. At this stage you might estimate costs: for example, if you install 10 hydrant outlets, 200 m of piping, onetypes,piping, and pump set, you might estimate Dhaka cost

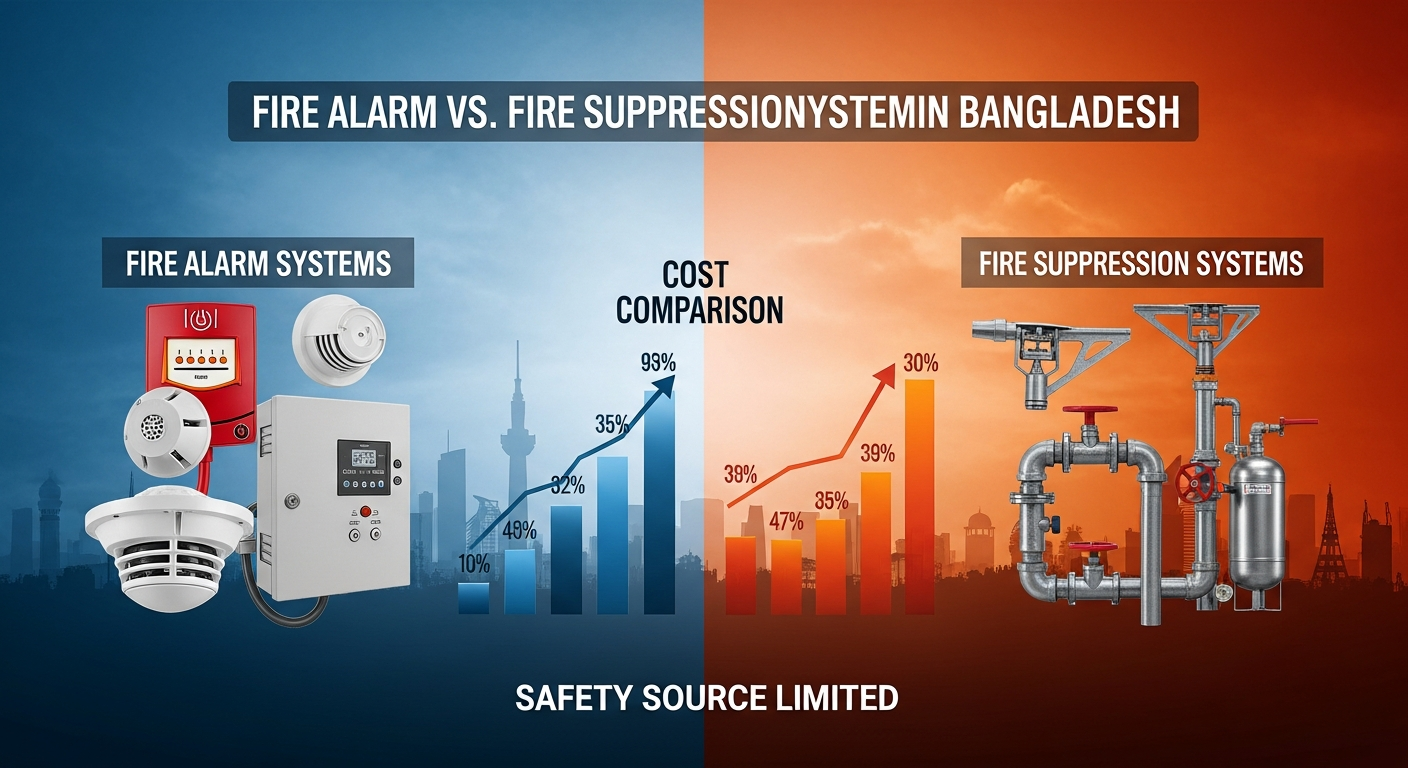

Cost Comparison: Fire Alarm vs. Fire Suppression Systems in Bangladesh

Introduction: Fire Safety as a Non-Negotiable Investment In Bangladesh’s rapidly urbanizing landscape, fire safety is no longer a compliance checkbox—it is a life-saving necessity. Every year, the country witnesses numerous commercial and residential fires that cost millions in property damage and, more tragically, human lives. Yet, when it comes to prevention, many businesses still ask a crucial question: Should we invest more in fire alarms or in full fire suppression systems? This cost comparison between Fire Alarm Systems and Fire Suppression Systems offers a practical guide for businesses, factories, and property developers. Understanding the financial and functional differences between the two can mean the difference between a timely response and a catastrophic loss. Fire safety experts often emphasize that “detection is half the battle, suppression is the victory.” This article dives deep into the economics of both systems in the context of Bangladesh—where safety budgets are often limited but the risks are alarmingly high. 1. Understanding the Two Systems: Detection vs. Action A Fire Alarm System primarily detects and alerts occupants of a potential fire. It includes smoke detectors, heat sensors, alarm panels, and sirens designed to trigger an immediate response. A Fire Suppression System, on the other hand, goes a step further. It not only detects fire but actively extinguishes it—using agents such as water, foam, gas, or chemical suppressants. Common systems include sprinkler systems, FM-200 clean agent systems, and CO₂ suppression units. In simple terms, alarms warn; suppression systems fight. Both are essential components of a comprehensive Fire Safety plan, but their costs and maintenance differ substantially. 2. The Cost Factor: What You Pay and What You Get The Fire Alarm cost depends largely on the building type, area coverage, and device quality. In Bangladesh, the average installation cost for a commercial fire alarm system ranges from ৳100 to ৳250 per square foot, depending on features such as addressable control panels, smoke sensitivity, and integration with central monitoring. A Fire Suppression System, by contrast, is more capital-intensive. Depending on the medium used (water, CO₂, or FM-200 gas), costs can range from ৳500 to ৳1,200 per square foot. Gas-based systems, though expensive, are preferred in data centers, server rooms, and high-value manufacturing plants because they minimize damage to sensitive equipment. To visualize, a 10,000 sq. ft. commercial building might expect the following costs: System Type Average Cost per sq. ft. Estimated Total Cost (10,000 sq. ft.) Fire Alarm System ৳150 ৳1,500,000 Water Sprinkler System ৳550 ৳5,500,000 Gas Suppression (FM-200) ৳1,000 ৳10,000,000 The initial numbers may seem high, but when compared to the potential losses from a single fire incident—often exceeding ৳50 million in industrial sites—the investment is undeniably justified. 3. Case Study: Lessons from a Garment Factory Incident In 2022, a mid-sized garment factory in Gazipur experienced an electrical short circuit that triggered a small fire in the storage unit. The factory had installed a modern fire alarm system but no suppression equipment. The alarm activated successfully, and workers evacuated in under 90 seconds. However, by the time the local fire service arrived—12 minutes later—nearly ৳15 million worth of fabric and machinery was lost. Contrast this with another facility in Narayanganj, which invested in a combined alarm and water mist suppression system. When a similar incident occurred, the system activated automatically, containing the fire within three minutes. Losses were under ৳2 million, mainly due to smoke exposure. The difference illustrates a vital truth: a fire alarm saves lives; a suppression system saves both lives and assets. 4. Long-Term Cost of Ownership: Maintenance and Durability A major consideration in fire safety investments is not just installation cost but maintenance and lifecycle expense. Fire Alarm Systems require periodic sensor calibration, battery checks, and software updates. Annual maintenance typically costs 5–8% of the installation value. Fire Suppression Systems, however, demand higher maintenance due to cylinder recharging, pressure testing, and inspection protocols. Their annual upkeep can range between 10–12% of installation costs. For instance, maintaining a ৳10 million FM-200 system could cost around ৳1.2 million annually. Yet, given its ability to suppress a fire before it spreads, this maintenance cost often pays for itself within the first avoided incident. 5. Return on Investment (ROI): The Economic Logic Many decision-makers hesitate to invest heavily in fire suppression due to its upfront price. However, ROI calculations tell a different story. Assume a medium-sized commercial property valued at ৳500 million. A suppression system costing ৳10 million would protect that investment from total loss. If the system prevents even a single catastrophic fire in 10 years, the return on investment exceeds 400%. In contrast, a standalone alarm system offers critical early warning but doesn’t stop the spread of fire—potentially limiting ROI in terms of property protection. 6. Expert Insights: Balancing Safety and Affordability Fire safety consultant Engr. Shahriar Rahman, who advises industrial facilities in Dhaka, explains: “In Bangladesh, many businesses look for short-term savings by choosing alarms only. But suppression systems are like insurance—expensive upfront, priceless during an emergency.” International fire protection engineer Dr. Alicia Morgan adds: “Global best practices recommend integrating both systems—alarms for detection, suppression for containment. Skipping either compromises the entire safety chain.” This dual-system approach aligns with NFPA 72 and NFPA 2001 standards, both of which outline comprehensive protection frameworks adopted worldwide. 7. Technology Trends: Smarter and Cheaper Fire Safety Ahead Modern fire protection technology is rapidly becoming more accessible. Smart fire alarm panels now use IoT connectivity to alert local fire services instantly via mobile apps. Meanwhile, newer suppression systems use eco-friendly agents that minimize environmental impact. FM-200 and Novec 1230 systems, though costly, are gaining popularity in data-driven industries like banking and telecom due to their clean and residue-free operation. Bangladeshi companies are also beginning to manufacture components locally, reducing import costs. This shift is expected to lower Fire Suppression System costs by up to 20% within the next three years. 8. Real Estate and Insurance Implications Developers and property owners often overlook how Fire Safety directly affects insurance premiums and property valuations. Buildings equipped with certified suppression systems can